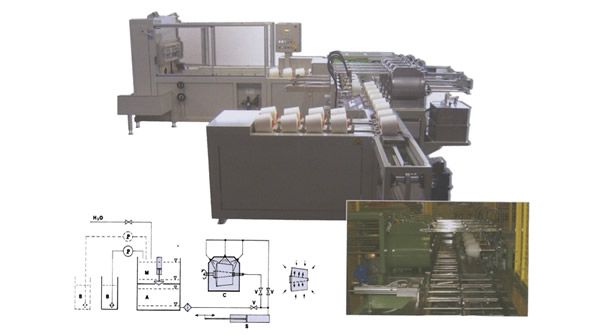

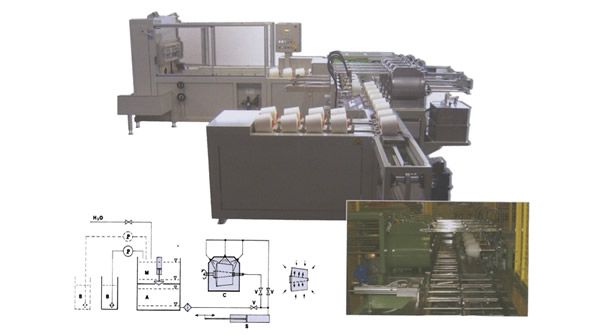

Automatic humidification machine of yarn bobbins Mod. Humidroc

The machine moistens the yarn bobbins introducing a quantity of prefixed and adjustable moisture into the bobbins itself. The introduction of moisture can be made from outside and, using perforated tubes, plastic or paper, also from inside by dosing an exact quantity of moisture. This quantity can be regulated by two switches which are placed on a panel; it’s total is shown on a display.

There are two working cycles. A centrifuge phase with adjustable speed which moistens from inside the tube and a slow phase which sprays the moisture on to the bobbins. In this case the moisture is atomized. The prerogative is that the quantity of moisture, so introduced, is absolutely constant for every single bobbin, since the dosage is made by volumetric pump. The complete diffusion of moisture happens in about 48 hours.

The machine humidify flax yarns and different kinds of auxiliary products can be added to the moisture. This operation allows to obtain: % of conventional and desired humidity into the bobbin before dispatch and, on following passages; greater and more regular slipping of the yarn; softer and more elastic yarns and consequently stronger againist breakage; less dust on the work-place; increase of the productivity of the machines; gain of % oiling and humidity after drying.

The machine can have one, two or four moistening chambers to moisten one, two or four bobbins at the same time and can be combined directly with the automatic packaging line of bobbins, i.e. as a completion of a line itself.